Your Benefit: Your Quality Requirements

- Home

- Kegelmann Technik GmbH

- Your Benefits

- Benefits for your Company

- Your Benefit: Your Quality Requirements

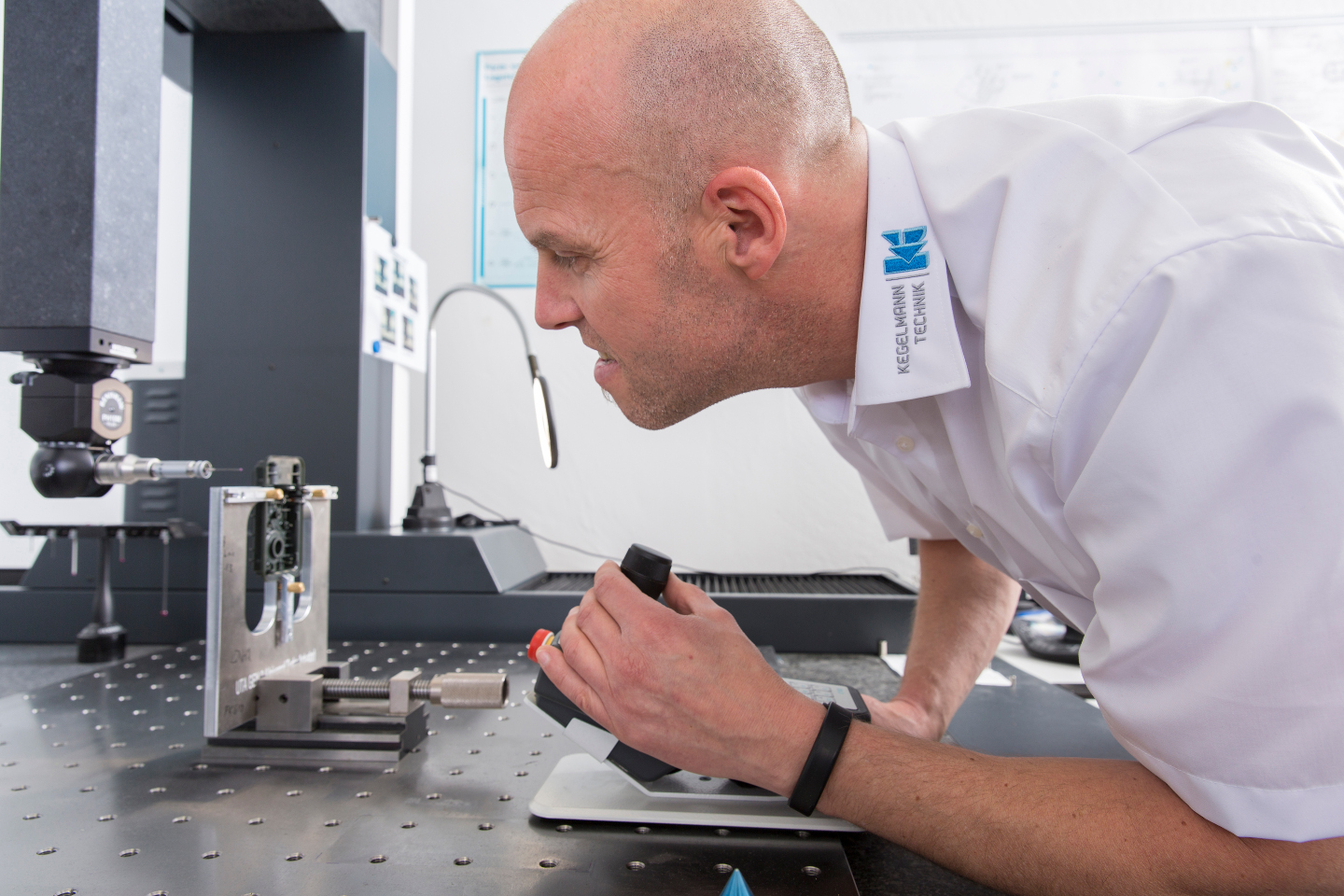

A Product has to be perfect

In the benefit for the customer we will not let anyone beat us.

Innovation cycles are getting shorter and customers are more demanding. A product may no longer mature during a long process, it must be perfect from the beginning. We support you with our know-how and our digital process chains for rapid prototyping and additive manufacturing.

By producing prototypes and products directly from the CAD dataset, a high degree of flexibility in design changes and thus an iterative quality improvement is possible. In addition, design changes to additive manufacturing processes in close collaboration with your development department will enable us to more than just meeting your specific requirements – precision and fit, durability and temperature resistance, flexibility and elasticity, lightweight construction and new geometries, colors, materials and material combinations.

We ourselves as well as our processes undergo regularly audits for the certifications according to ISO 9001, IATF 16949 (Automotive) and EN 9100 (Aviation). We are happy to support you with an initial sample test report (PPAP) before the start of series production. All important information on the corresponding requirements and tests with setpoints and established actual values are summarized and documented in the initial sample test report.